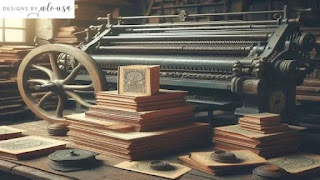

Offset Printing Paper Types: 3 Widely Used Materials

Embark on a captivating journey through the heart of offset printing project, where the choice of paper types weaves an intricate narrative, adding layers of texture and color to the canvas of every print. Explore the profound impact each paper type brings, creating a symphony that resonates with appreciation for the artistry and precision in the world of offset litho. Explore the rich world of offset printing paper types , unraveling their impact on the printing journey. Takeaways Offset lithography form the soul of the printing realm, a rich interplay where each paper variety contributes to the artistry and precision of the final masterpiece. The diverse array, from uncoated classics to glossy marvels, adds a touch of sophistication to the world of offset printing. This intricate dance of textures and finishes becomes the captivating visual and tactile experience of the printed material. As one delves into the nuances of these papers, the culmination, the final printed prod...